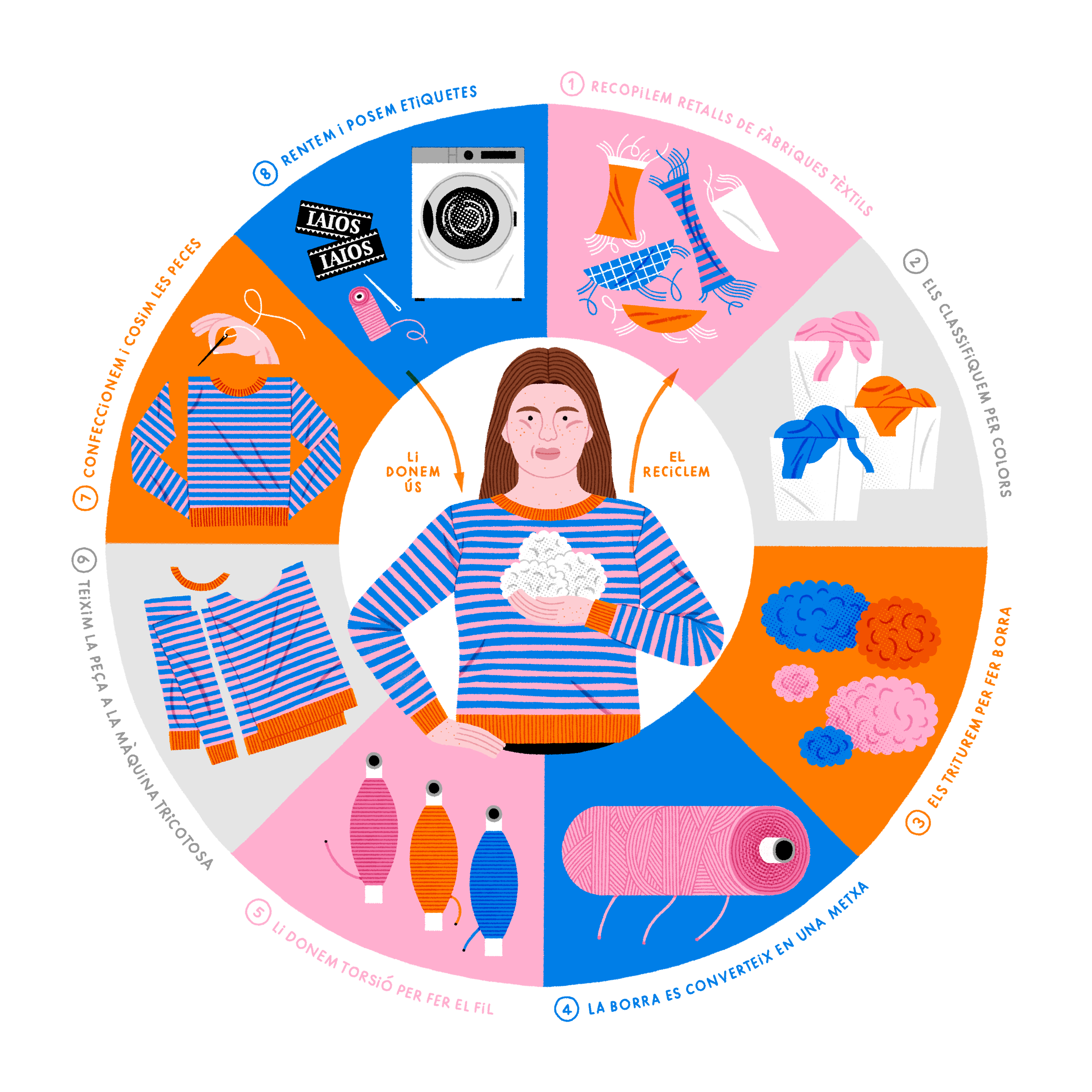

HOW WE DO IT

IAIOS recovers the sweater of a lifetime; the one that was made in a sustainable way, recycling and taking advantage of raw materials and above all, that lasted for many years. In this way, our sweaters are made recovering a recycling technique in disuse, the regenerated wool that consists of recycling scraps to make yarn.

In addition, we are a sustainable fashion project that wants to reduce waste in all facets of the life of a sweater. For this reason, once a year we repair the sweaters that need it and we send them back to the customer.

Recycled yarn:

The yarn in our sweaters is 100% recycled using a zero waste process. The spinning process consists of recycling leftover trimmings from textile mills to make yarn again. It is a process that does not generate waste and avoids going through the dyeing process (which is very polluting for water) and also saves 99% of water consumption.

Locally manufactured:

Our sweaters are of proximity, thus avoiding the great environmental cost of long distance transport of products by plane, boat or truck. The entire production process takes place between Olot, Igualada and Granollers, thus favoring the economy of the area and ensuring decent work and transparency.

Circular design:

Once it has reached the end of its useful life, the customer can send the sweater to us and we will make sure it is recycled again. Our sweaters have no buttons, zippers or other materials that may hinder the recycling process. Also the durability of the garment is very important to us, that's why we have designed a modern pattern with a timeless style, made to last for many winters.

Sweater repair:

We want our sweaters to last for many years and for this reason, once a year, we offer a repair service. So, in summer we pick up all the sweaters that need it and we fix them so that the following winter they will be as good as new.

Scraps

Scraps are recovered from textile mills such as spinning mills, garment factories, etc., and the pieces containing wool or wool with acrylic are sorted.

Ranking

These remnants are separated by color and bundles are made with the different shades.

Delete

The bales are carded to separate the fibers from the fabric. This results in a flock that has a texture similar to that of virgin wool. The flock of different shades can be mixed as in a painter's palette. In this way we avoid the dyeing process.

Wick

With the flock, the spinning process can begin. The first step is to put the fibers in the form of a churro or wick and wind it around a cylinder.

Torsion

By twisting the wick, a much stronger and thinner yarn is obtained, which is wound into 1 kg cones.

Fabric

With the yarn cones you can design and knit the pieces that will be part of the sweater. In general: front, back, sleeves and neck.

Confection

The different pieces are sewn together. When making adjustments to the pattern, the scraps that are generated go back to point 1.

Finishes

The ready-made garments are washed to eliminate unpleasant odors. They are also ironed and the size, brand and composition labels are sewn on.